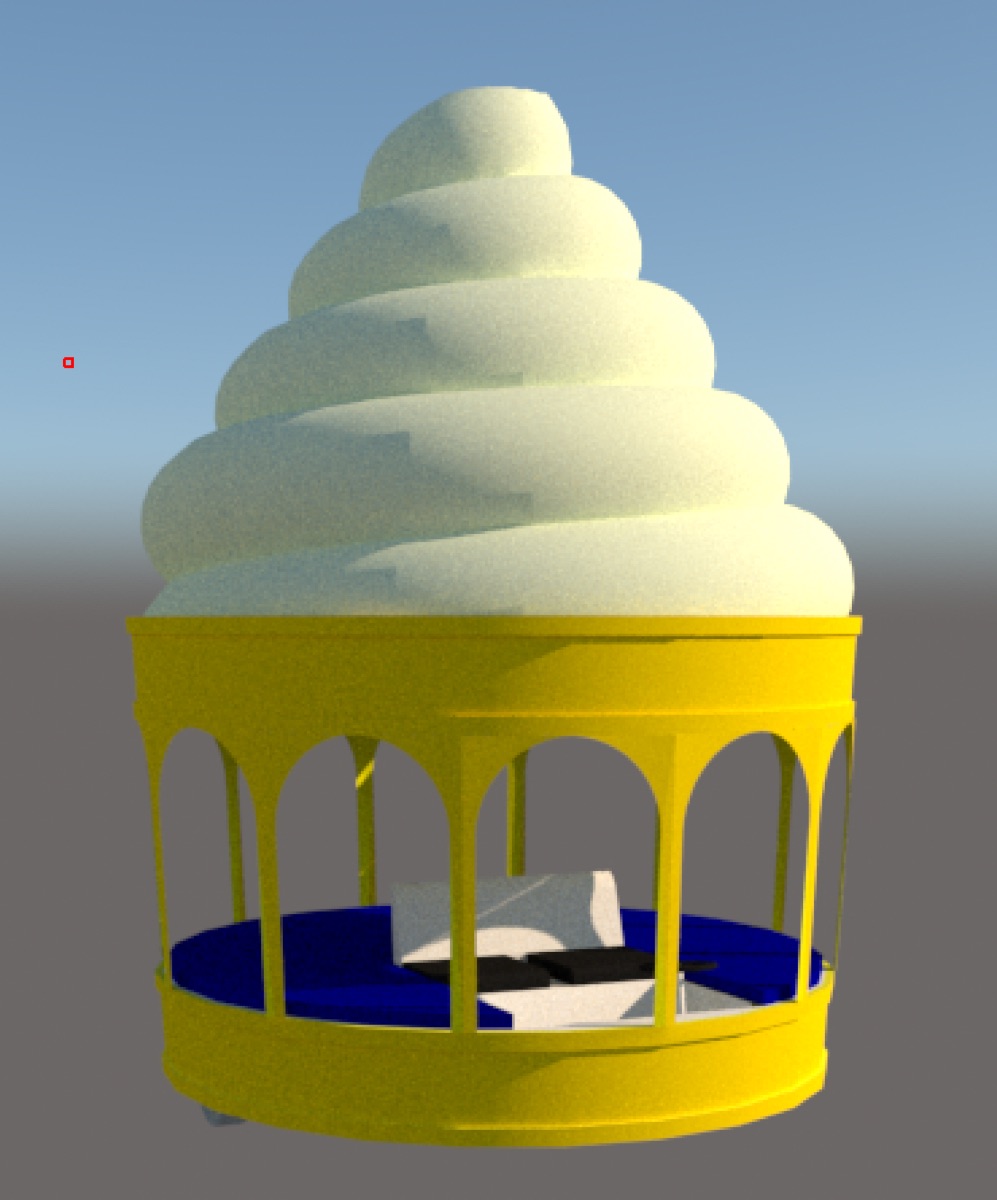

Overview

Full-scale art car build for a frozen yogurt brand, fabricated in our San Francisco, California workshop. Mixed-material construction combining a steel subframe with shaped foam, fiberglass, and custom paint. The project moved from concept sketches through CAD modeling to physical fabrication in a compressed timeline. Designed for road use with all structural components engineered for vibration and weather. Built for a Bay Area brand activation.

Fabrication Process

Started with a 3D scan of the vehicle, then modeled all additions in Fusion 360. Steel subframe was welded to existing vehicle mounting points. Shaped EPS foam was CNC hot-wire cut, then laminated with fiberglass and finished with automotive paint.

Materials

- Steel (subframe)

- EPS foam (sculpted forms)

- Fiberglass

- Automotive paint